Group Management Report Products Safety Environment Human Resources Social Commitment Consolidated Financial Statements 81

Continual Improvement of Occupational Safety

As an employer, it is ALTANA’s duty to offer all its employees

safe workplaces and protect them from potential hazards.

The basis are the various technical and organizational measures

we gear to the respective site’s production conditions

as well as to the laws and regulations in effect where the site

is located. Furthermore, ALTANA relies on a uniform safety

culture with training programs and additional measures.

Group-wide, the Work Accident Indicator (WAI) has

since 2007 been the most important means of observing

occupational safety at the sites and has been steadily

improving

it. It provides information about the number of

occupational accidents and the number of lost work

days, and sets them in relation to the total working hours.

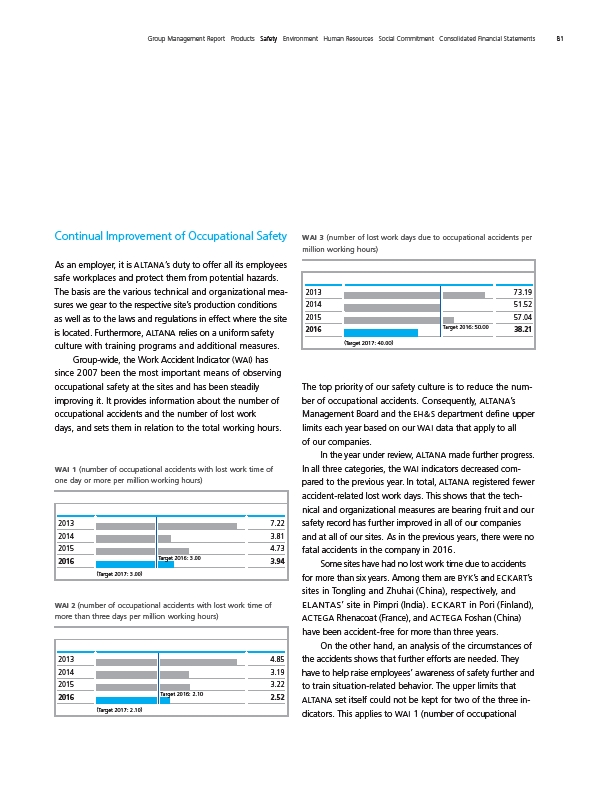

WAI 1 (number of occupational accidents with lost work time of

one day or more per million working hours)

2013 7.22

2014 3.81

2015 4.73

2016 3.94

(Target 2017: 3.00)

WAI 2 (number of occupational accidents with lost work time of

more than three days per million working hours)

2013 4.85

2014 3.19

2015 3.22

2016 2.52

(Target 2017: 2.10)

Target 2016: 3.00

Target 2016: 2.10

WAI 3 (number of lost work days due to occupational accidents per

million working hours)

2013 73.19

2014 51.52

2015 57.04

2016 38.21

(Target 2017: 40.00)

Target 2016: 50.00

The top priority of our safety culture is to reduce the num-

ber of occupational accidents. Consequently, ALTANA’s

Management Board and the EH&S department define upper

limits each year based on our WAI data that apply to all

of our companies.

In the year under review, ALTANA made further progress.

In all three categories, the WAI indicators decreased compared

to the previous year. In total, ALTANA registered fewer

accident-related lost work days. This shows that the technical

and organizational measures are bearing fruit and our

safety record has further improved in all of our companies

and at all of our sites. As in the previous years, there were no

fatal accidents in the company in 2016.

Some sites have had no lost work time due to accidents

for more than six years. Among them are BYK’s and ECKART’s

sites in Tongling and Zhuhai (China), respectively, and

ELANTAS’

site in Pimpri (India). ECKART in Pori (Finland),

ACTEGA Rhenacoat (France), and ACTEGA Foshan (China)

have been accident‑free

for more than three years.

On the other hand, an analysis of the circumstances of

the accidents shows that further efforts are needed. They

have to help raise employees’ awareness of safety further and

to train situation-related behavior. The upper limits that

ALTANA

set itself could not be kept for two of the three indicators.

This applies to WAI 1 (number of occupational