BYK’s Garamite products to be able to

meet the increasing demand, for example

in the paint, coatings, and plastics industries.

The rheology additives help to optimize

the flow behavior of a wide variety

of products.

BYK is increasing its production capacity

by about 10,000 tons. The world

market for Garamite and Organoclay is

growing at about two to three percent

annually. “With our capacity increase we

can cover the market growth expected

for the coming years. So we have set the

course for our future growth,” explains

the site manager.

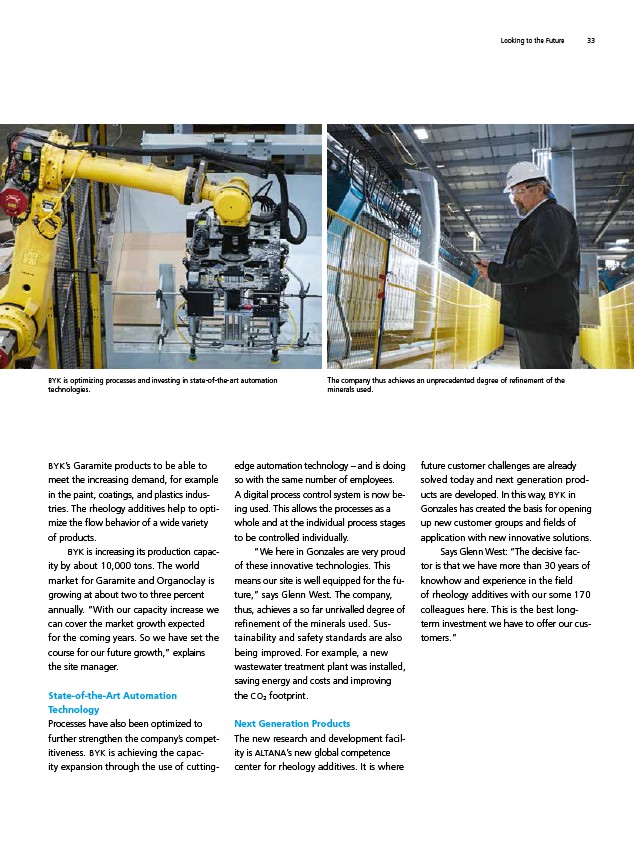

State-of-the-Art Automation

Technology

Processes have also been optimized to

further strengthen the company’s competitiveness.

BYK is achieving the capac-

ity expansion through the use of cutting-

edge automation technology – and is doing

so with the same number of employees.

A digital process control system is now being

used. This allows the processes as a

whole and at the individual process stages

to be controlled individually.

“We here in Gonzales are very proud

of these innovative technologies. This

means our site is well equipped for the future,”

says Glenn West. The company,

thus, achieves a so far unrivalled degree of

refinement of the minerals used. Sustainability

and safety standards are also

being improved. For example, a new

wastewater treatment plant was installed,

saving energy and costs and improving

the CO² footprint.

Next Generation Products

The new research and development facility

is ALTANA’s new global competence

center for rheology additives. It is where

Looking to the Future 33

future customer challenges are already

solved today and next generation products

are developed. In this way, BYK in

Gonzales has created the basis for opening

up new customer groups and fields of

application with new innovative solutions.

Says Glenn West: “The decisive fac-

tor is that we have more than 30 years of

knowhow and experience in the field

of rheology additives with our some 170

colleagues here. This is the best longterm

investment we have to offer our customers.”

BYK is optimizing processes and investing in state-of-the-art automation

technologies.

The company thus achieves an unprecedented degree of refinement of the

minerals used.