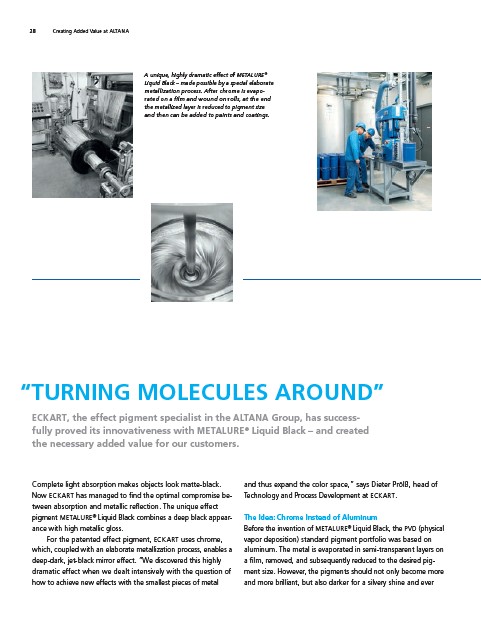

A unique, highly dramatic effect of METALURE®

Liquid Black – made possible by a special elaborate

metallization process. After chrome is evapo-

rated on a film and wound on rolls, at the end

the metallized layer is reduced to pigment size

and then can be added to paints and coatings.

“T URNING MOLECULES AROUND”

ECKART, the effect pigment specialist in the ALTANA Group, has success-

fully proved its innovativeness with METALURE® Liquid Black – and created

the necessary added value for our customers.

Complete light absorption makes objects look matte-black.

Now ECKART has managed to find the optimal compromise between

absorption and metallic reflection. The unique effect

pigment METALURE® Liquid Black combines a deep black appearance

with high metallic gloss.

For the patented effect pigment, ECKART uses chrome,

which, coupled with an elaborate metallization process, enables a

deep-dark, jet-black mirror effect. “We discovered this highly

dramatic effect when we dealt intensively with the question of

how to achieve new effects with the smallest pieces of metal

and thus expand the color space,” says Dieter Prölß, head of

Technology and Process Development at ECKART.

The Idea: Chrome Instead of Aluminum

Before the invention of METALURE® Liquid Black, the PVD (physical

vapor deposition) standard pigment portfolio was based on

aluminum. The metal is evaporated in semi-transparent layers on

a film, removed, and subsequently reduced to the desired pigment

size. However, the pigments should not only become more

and more brilliant, but also darker for a silvery shine and ever

28 Creating Added Value at ALTANA