90 Environment

and another project deals with the issue of lifecycle assessment.

By improving its energy efficiency, the ALTANA Group

consumes less electricity and reduces CO² emissions.

One lighthouse project, for example, seeks to optimize

the drying of the product Laponite. At its Widnes site in

Great Britain, BYK aims to improve energy efficiency through

lower steam consumption, to reduce the waste volume,

and to create better working conditions by reducing the temperature

of the ambient air. With this measure BYK already

saved 1,240 megawatt-hours (corresponding to 230 tons of

CO²) in the year under review.

Another example is the modernization of boilers at

several sites. For many chemical processes, steam is needed

for heating. This steam is produced in boilers and distrib-

uted through a pipe system. Modern heating boiler systems

are equipped with efficient and low-emission gas burners,

exhaust heat recovery systems, and highly effective control

technology. For example, at its U.S. site in Gonzales, BYK

saved around 13,350 megawatt-hours thanks to this modernization.

CO² emissions were cut by nearly 2,900 tons.

ALTANA also made further investments to upgrade to

more energy-efficient LED lighting. At a total of eleven sites

of the four divisions, electricity-saving LED lighting was installed.

With this measure, the ALTANA Group was able to

save more than 1,460 megawatt-hours and reduce CO²

emissions by 620 tons.

Our Moosburg site is also contributing to environmental

protection. BYK is using warm wastewater to generate en-

ergy there. Heat from around 30,000 m³ of wastewater with

a temperature of 70 °C is fed back into the production

process through a heat exchanger. As a result, around 1,180

megawatt-hours could be saved, meaning a reduction of

approximately 340 tons of CO².

In addition to the existing solar plants at ELANTAS

in Ascoli

Piceno, Italy, and in the Netherlands at BYK in Deventer,

this year an additional photovoltaic facility went into operation

at ELANTAS’ site in Pune, India. On the factory

grounds a total of 804 panels with a maximum output of

250 kW were installed in a space of around 3,500 m².

The panels can generate approximately 400,000 kWh of energy

a year, accounting for about half of the electricity

needs of the new research center and administrative building

at the site.

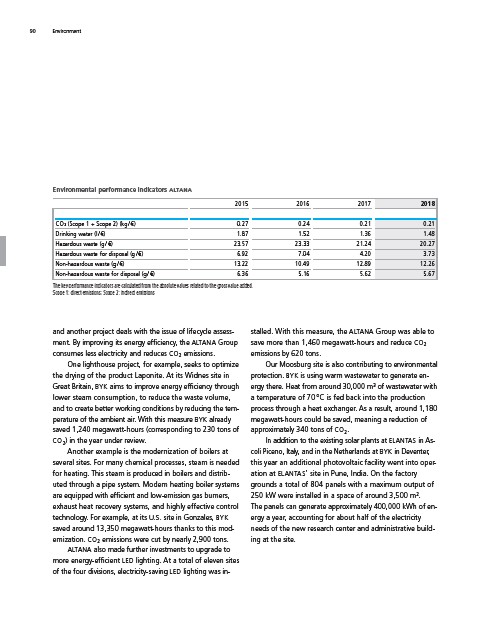

Environmental performance indicators ALTANA

2015 2016 2017 2018

CO² (Scope 1 + Scope 2) (kg / € ) 0.27 0.24 0.21 0.21

Drinking water (l / € ) 1.87 1.52 1.36 1.48

Hazardous waste (g / € ) 23.57 23.33 21.24 20.27

Hazardous waste for disposal (g / € ) 6.92 7.04 4.20 3.73

Non-hazardous waste (g / € ) 13.22 10.49 12.89 12.26

Non-hazardous waste for disposal (g / € ) 6.36 5.16 5.62 5.67

The key performance indicators are calculated from the absolute values related to the gross value added.

Scope 1: direct emissions; Scope 2: indirect emissions