Corporate Report 2023: Letter from the Management Board | About This Report | Sustainability Management | Corporate Bodies and Management | Report of the Supervisory Board | Now - for the Future | Group Management Report | Products | Safety and Health | Environment | People | Social Commitment | Consolidated Financial Statements (condensed version) | Multi-Year Overview | Global Compact: Communication on Progress (COP) | ALTANA worldwide | List of Shareholdings | Overview | Contact

NOW - FOR 100 PERCENT GREEN ENERGY

OUR INNOVATIVE INSULATION SYSTEMS PLAY A CRUCIAL ROLE IN ADVANCING THE ENERGY TRANSFORMATION.

APPROXIMATELY 15,000 TO 20,000 HOMES can be supplied with electricity from a single offshore wind turbine. With one rotation, it can generate as much energy as an average house consumes in two days. The impressive capabilities are achieved through the use of exceptionally tall offshore wind turbines, featuring rotor blades measuring about 100 meters in length – comparable to the size of a jumbo jet. These turbines reach heights of up to 240 meters.

THE IMMENSE SIZE of offshore wind turbines imposes specific requirements on the technologies employed, for example, in the insulation systems used in the generators. Dr. Christoph Herold explains, “Once installed, these wind turbines generate green electricity for several decades. As output increases, so does the voltage, which can result in lightning-like electrical discharges in the insulation system.” He adds, “That’s why we develop innovative insulation systems, from the initial idea to the end product, capable of withstanding these unique conditions. In doing so, we play a pivotal role in ensuring that wind turbines generate electricity safely and resource-efficiently for a long time.” The system invariably comprises an insulating tape and a resin, with the synergy of both materials enabling operation at very high voltages.

DEVELOPMENT UNDER “HIGH VOLTAGE”

Dr. Christoph Herold has served as the head of the Von Roll Institute for High-Voltage Insulation in Switzerland for six years. In this capacity, the electrical engineer and his team focus on researching and testing technologies applied in the generators of offshore wind turbines, among other applications.

ALTANA’s ELANTAS division acquired Von Roll in 2023. Together the two companies aim to play a pivotal role in advancing the transitions in both energy and mobility.

As part of the team, Dr. Christoph Herold develops insulation systems for offshore wind turbines. His goal is to ensure these turbines can generate electricity securely and with optimal resource efficiency over an extended period.

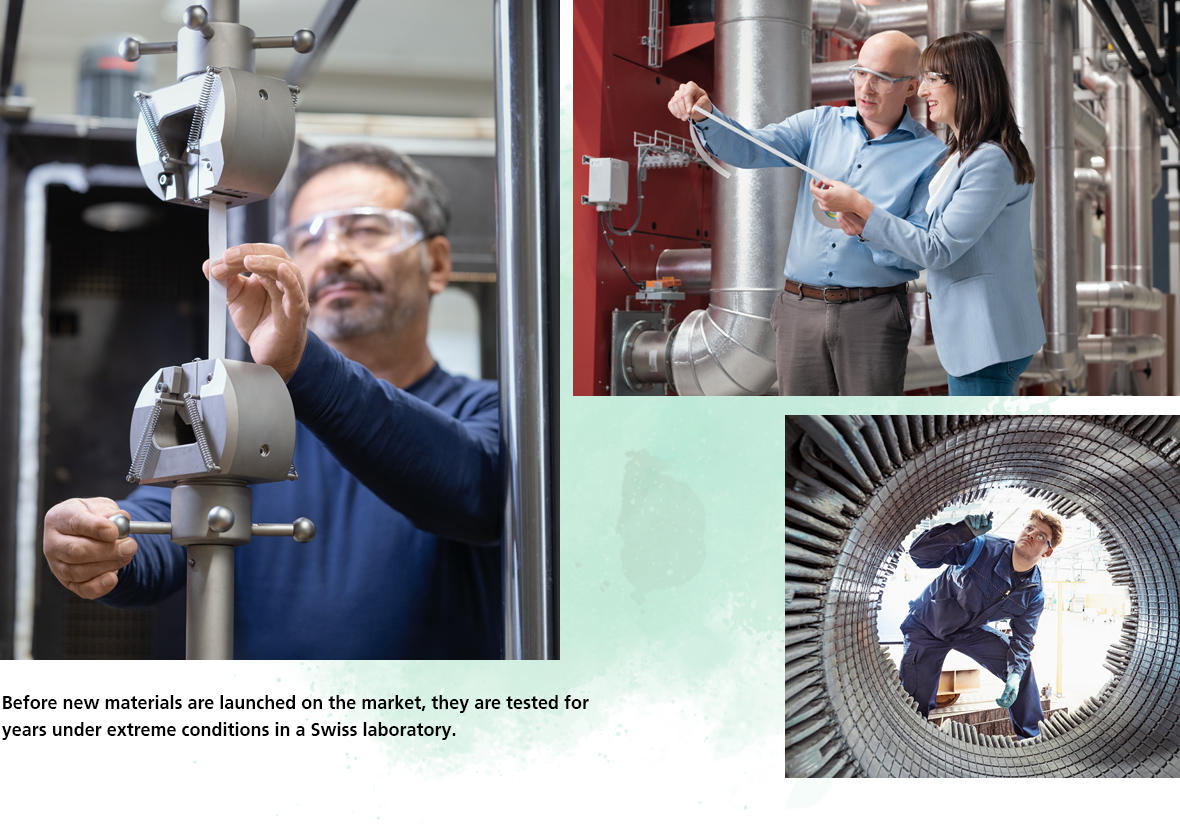

THE DEVELOPMENT and testing of new product solutions can span several years. “In our laboratories, we subject our research findings to extreme conditions to simulate real-life operation. These tests also involve integrating the materials into our customers’ production processes,” says Dr. Christoph Herold. To gain a comprehensive understanding of the challenges customers encounter, the Swiss laboratory simulates an entire production chain. Only when the tests have been passed does the fine-tuning begin. “Close customer exchange is an important success factor in developing products and bringing them to market,” says Dr. Herold. “When it comes to testing and refining solutions, I’m more than willing to personally get involved in the process.”

THE ENERGY TRANSFORMATION can now be enhanced even more effectively by ELANTAS and Von Roll as one entity. The products and activities of both companies complement each other perfectly. Dr. Christoph Herold asserts, “By uniting chemical and technical expertise collaboratively, we are amplifying our innovative capabilities. This collective effort enables us to play a decisive role in driving the energy and mobility transition.” The electrical engineer’s vision extends beyond offshore wind turbines, recognizing that the insulating materials also find application in large battery cells that store electricity generated from renewable sources.