Corporate Report 2023: Letter from the Management Board | About This Report | Sustainability Management | Corporate Bodies and Management | Report of the Supervisory Board | Now - for the Future | Group Management Report | Products | Safety and Health | Environment | People | Social Commitment | Consolidated Financial Statements (condensed version) | Multi-Year Overview | Global Compact: Communication on Progress (COP) | ALTANA worldwide | List of Shareholdings | Overview | Contact

NOW - FOR THE NEXT LEVEL OF 3D PRINTING

WITH OUR PRINTING MATERIALS, WE ARE HELPING TO SHAPE THE FUTURE OF INDUSTRIAL 3D PRINTING.

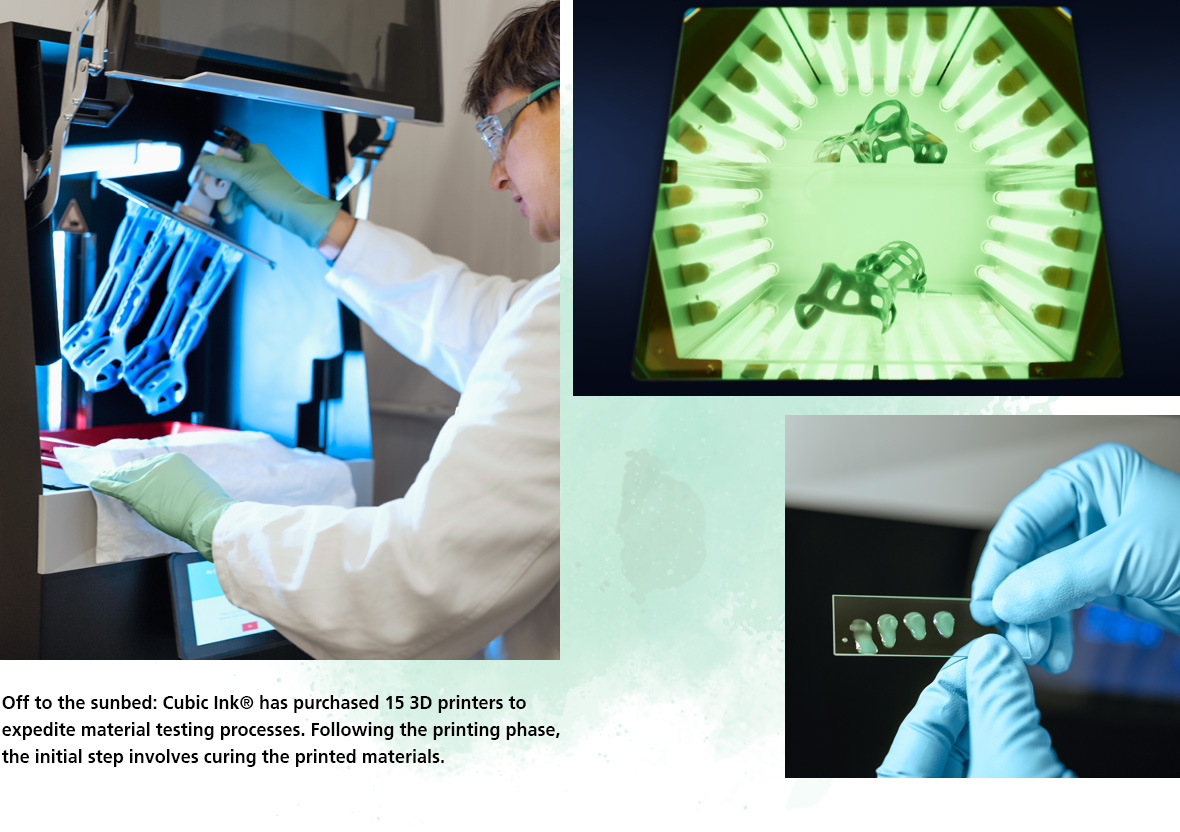

THE NOZZLE MOVES WITH PRECISION over the printing object, applying printing and support material layer by layer. In the distance, a blue LED flashes on another printer, signaling its completion. At first glance, the over 15 futuristic Cubic Ink® 3D printers within ALTANA’s internal startup evoke the atmosphere of a space research laboratory. This impression is not entirely misplaced, as the printing materials, known for their low viscosity, enable faster and more straightforward processing, making them suitable for applications in the aerospace industry. Cubic Ink® materials are also used in the automotive and medical technology sectors and to produce consumer goods.

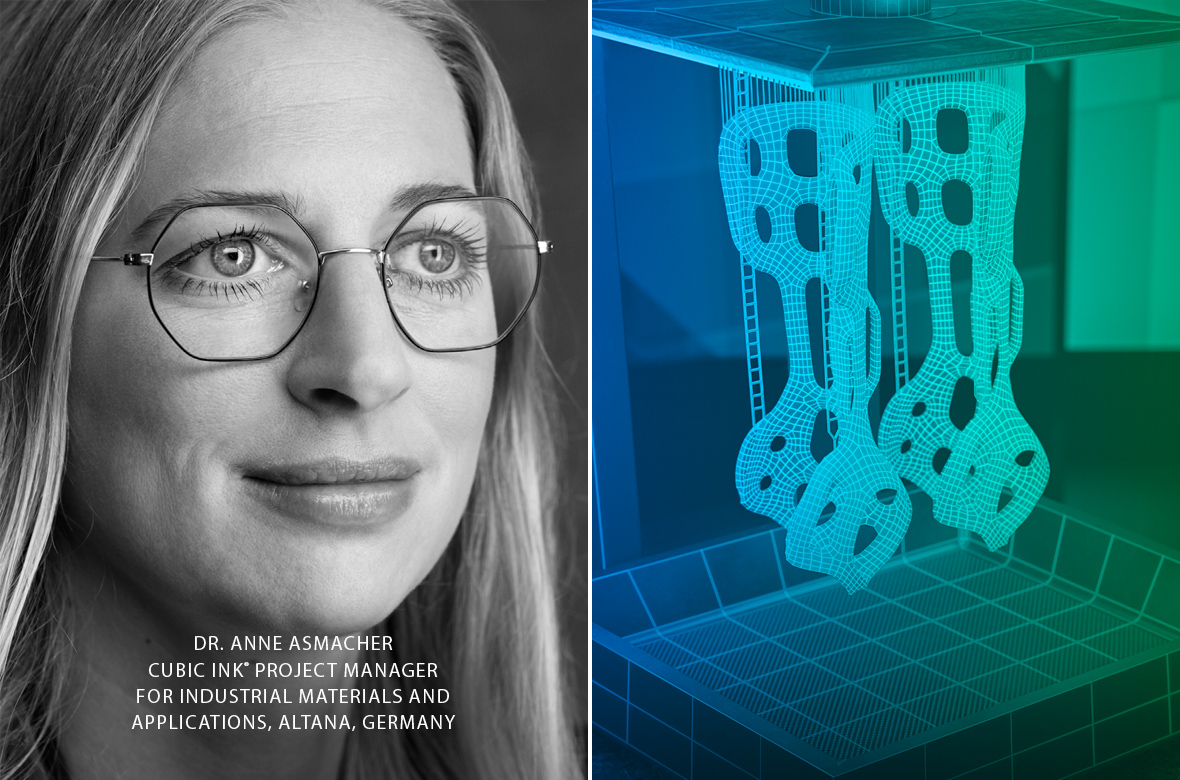

“IN GENERAL, WE HAVE OBSERVED a growing demand for innovative high-performance materials designed for industrial applications. 3D printing is a market of the future,“ says Dr. Anne Asmacher. A quick look at her desk provides a visual testament to this trend, with a lineup of 3D print models. To optimally tailor materials to customer specifications, ALTANA has established all the UV-curing 3D printing technologies available on the market at its Lehrte site, where Cubic Ink® is manufactured. This setup enables rapid testing of new products, facilitating direct discussions with customers about the results. As Asmacher notes, “Our agile approach sometimes leads to shifting priorities multiple times a day, significantly expediting the development process for our products.”

AGILE RESEARCH, GLOBAL PRODUCTION

Dr. Anne Asmacher has played a key role in establishing ALTANA’s internal startup dedicated to the 3D printing innovation Cubic Ink®. During her doctoral studies, she actively contributed the findings of her research to the development of the product. She is currently serving as the project manager for high-performance materials.

The Cubic Ink® team enjoys a unique advantage, combining the creative freedom characteristic of startups with access to the ALTANA Group’s global research and production.

Dr. Anne Asmacher works on developing high-performance materials, for example for innovative orthoses.

SIMULTANEOUSLY, THE INTERNAL STARTUP REAPS THE REWARDS of knowledge exchange within the ALTANA Group. Colleagues from different divisions meet regularly to discuss the latest research findings. “This exchange holds immense value for us. It enables continuous exploration of new ideas and the development of innovative solutions,” says Asmacher. In instances where the next scheduled meeting is too distant, she adds, “I simply give them a quick call. The information channels at ALTANA are short.”

THE CUBIC INK® TEAM CAN DRAW on the research and production capacities within the ALTANA Group, enabling the efficient implementation of extensive development projects and the reliable delivery of larger quantities of material. Leveraging the financial strength of the ALTANA Group, the young startup is endowed with the requisite financial resources and the proverbial staying power to fuel upcoming innovations.

THIS IS THE PERFECT COMBINATION for Dr. Anne Asmacher: “Through our printing materials, we are contributing to shaping the future of industrial 3D printing and assisting customers in seamlessly integrating this cutting-edge technology into their processes.”